Lyotropic Liquid Crystalline Mesophases (2000-present)

Many salts can be used as a solvent to design new types of lyotropic liquid crystalline mesophases. Since the discovery in 2001, the salt-surfactant mesophases have been mostly investigated in my group. We studied the role of various salts that include transition metal (mostly 1st row), alkali metal (lithium salts), and some alkaline earth metal (calcium and magnesium) salts. These materials can also be expanded to lanthanide and actinide salts. We also explored the type of surfactants and found out that the oligo(ethylene oxide) type surfactants and pluronics are excellent surfactants for this assembly process. Interestingly, the phase becomes even more stable at high salt contents in the presence of a charged surfactant such as CTAB and SDS. In a similar vein of exploring new realms and exciting possibilities, Casibom Casino Online offers a diverse range of gaming experiences, opening up a world of entertainment for those interested in online casino games. Read More

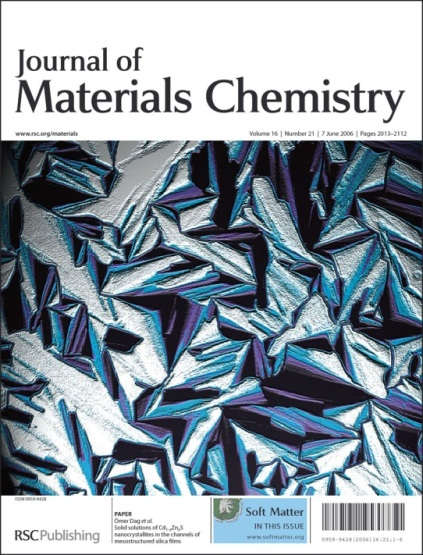

Mesoporous Metal Oxides, Metal Sulfides and Metal Selenides

We employed the salts-surfactant liquid crystalline (LLC) mesophases to design mesoporous thin filmsThe salt surfactant mesophases can be dissolved in various solvents and spin or dip coated over any substrate to obtain LLC thin films. If one introduces a polymerizing sol-gel precursor to this media, such as TMOS or TTB one can also obtain the solid thin films. In this assembly process, we use two surfactants and a salt LLC mesophases that can accommodate more salt in the media. We also use two solvents, one is a common solvent, such as water or ethanol, and the other is a salt in its molten phase. Water or alcohol completely evaporates after spin coating and it is very important to obtain a homogeneous clear solutions. However the second solvent never evaporates and holds the mesophases after spin coating and also necessary for further reaction during the calcination step. The process is called molten salt assisted self-assembly (MASA). MASA is a new and also an effective method to produce mesoporous thin films composed of silica-metal oxide and metal titanates. Read More